constructionequipmentmag.com

21

'20

Written on Modified on

CUMMINS News

The Worksite of The Future by Cummins

As the construction industry evolves into the future, how will the equipment be managed and powered? Steve Nendick, Marketing Communications Director at Cummins is looking to see how the developing innovations will impact efficiency and productivity and how worksites could look going forward.

Key features include a diverse mix of power sources; diesel, hybrid and full electric applications, with the required battery charging capability. Reactive decision making will be a thing of the past, with worksite managers relying on digital technologies to support a full range of power solutions.

The Power of Choice

Today’s construction sites predominantly use diesel power. Its proven reliability, performance, and flexibility to support a wide variety of duty cycles, mean diesel will remain an important foundation of worksites for many years to come.

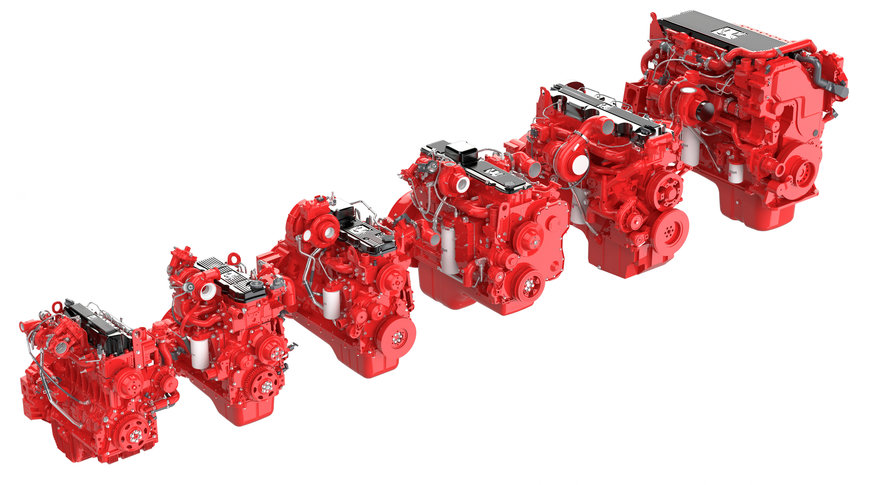

Heavy-duty applications like bulldozers are powered by Cummins’ Performance Series, the company’s cleanest and most powerful line up to date. These engines have on average over 10% higher power and 20% higher torque in a smaller, lighter package while at the same time achieving reduced emissions and operating costs. These improvements are the foundation for the future of diesel.

Cummins understands the market need for alternative power, and is working closely with customers and environmental agencies, to develop sustainable, efficient and reliable power solutions to work alongside advanced diesel. Recent investments by include new power technologies such as battery, hybrid and hydrogen fuel cell capability. To date, over 11 million miles of experience in electric and hybrid power has been accumulated across a variety of applications.

The industry has seen initial interest in electric machines for compact equipment such as mini-excavators to provide low noise and zero emission in urban environments. Cummins has developed power for a 3.5-ton electric excavator, with eight battery modules connected in a series configuration and providing total energy of 35 kWh. The battery modules use lithium-ion technology to achieve high energy density for a long zero emission range.

The expectation is that many compact applications will move to electric. For more demanding duty cycles, larger equipment including earthmoving applications, like the bulldozers or excavators, will rely on diesel power. Applications such as mobile cranes would work effectively and efficiently with hybrid power.

As the cost of ownership becomes more competitive with current solutions and contractor confidence increases, the growth of electric power is inevitable. Market enablers such as government subsidies and growing availability of charging infrastructure will be needed to support the higher numbers of electric and hybrid systems.

Charging for work

Future worksites will likely include charge stations which would power equipment such as electric wheel loaders or mini-excavators. Charge management of new electric technologies will use connectivity to monitor and coordinate the availability of energy, charger proximity, and eventually could include self-directed platforms that support autonomous machinery.

In the future, worksite managers will need to plan for energy consumption and coordinate fuel and energy delivery, across a wider range of power sources. Energy consumption and charging schedules will play a pivotal part in what the charging infrastructure for each site will look like. Decisions on whether to tie into the grid, leverage solar power, use generators or rely on portable charging stations will be made based upon the location and projected energy consumption over the life of the project.

Cummins will be positioned to offer a variety of charging options to support electrified machines. Fixed charge towers will be suitable for diverse, high power and high voltage fleet charging applications. These products are expandable to account for future planning and growth as on-site demand increases. Portable energy storage solutions could also be available to support non-grid enabled charging and potentially provide batteries with a useful second life.

Work in the dirt, manage efficiency in the cloud

To keep the worksite running, managers will be tasked with planning maintenance schedules and consumables such as oil, filters, coolant and replacement parts to ensure operations work efficiently and downtime is kept to a minimum. As the world makes the shift to digital, new technologies are expected to facilitate efficiency gains in areas like this. The work may be done in the dirt, but business productivity will be refined in the cloud through connected solutions and automated technologies.

Cummins Connected Solutions offer a complete end to end suite of system monitoring, reporting, over-the-air programing and smart charge management services designed to support the construction market. From remote equipment diagnostics and calibrations to power generation and electrified charging support, Cummins connected technologies enable digital applications, product enhancements and service integrations that all work together to keep worksites operating at peak performance with less downtime and more streamlined service and maintenance workflows.

In the event a technician is needed, Cummins’ service vehicle of the future has the Cummins PowerDrive system installed. It switches in real time between hybrid and electric modes for the best fuel efficiency in any driving condition. The vehicle is configured with exportable grid quality electric power to recharge equipment, run job site tools, or provide emergency power.

Cummins global service and support network will be connected to every customer and every worksite as the future evolves.

The company will lead in the growth of emerging technologies by applying over 100 years of engineering experience to deliver advanced power solutions in the same innovative and dependable way it has done with diesel power. Cummins will continue to partner with customer to ensure their success.

www.cumminseurope.com